Semiconductor

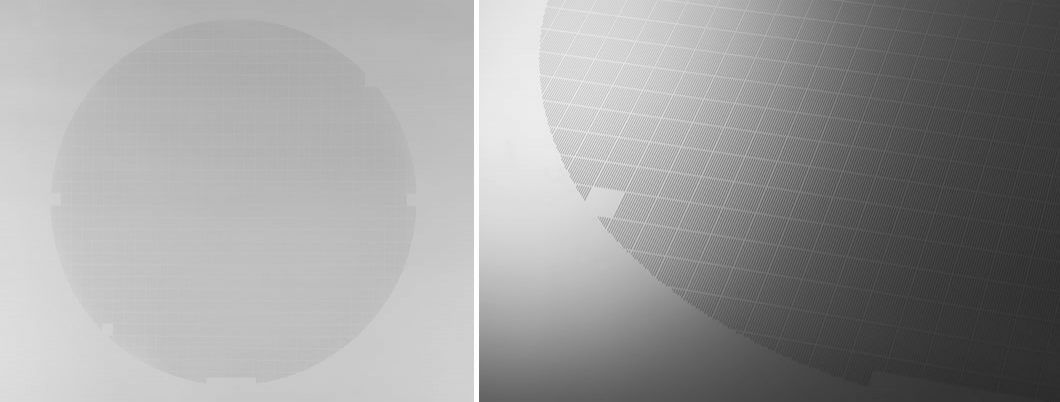

RITEK’s CSP (Chip Scale Package) & WLP (Wafer Level Package) is used for Semi-Conducting Business. It is a tool appear in semi-conducting manufacture process, which is to pin point the location for the machinery.

Metal Mask

● RITEK is a globally leading media storage corporation, which is famous for manufacturing CD, DVD, and Blue Disc. RITEK uses LIGA-like technology, which is a part of stamper technology for CD, to develop a micro-precision tool----electroforming stencils. RITEK has been studying and manufacturing electroforming stencils since 2008. RITEK now dominates electroforming stencils in IC packages. Moreover, RITEK also manufactures etching stencils to fit the product diversity of the market. An etching stencil is widely used and bought by international and top-ranking IC package companies.

● Electroforming or etching stencils is mainly applied to ball drop and solder paste printing in IC packages, IC substrate and other IC-related industries. RITEK electroforming and etching stencils have their features respectively, so the customers have various choices and will be satisfied. RITEK has been offering excellent and good-quality products and considerate service in order to give customers an amazing experience.

I. Electroforming stencil

1. Solder Paste Application

RITEK electroforming stencils with good-shaped openings, smooth side walls, and high-precise alignment make solder paste on substrate result in great height and uniformed width. The solder paste is also be accurately dropped on welded pad by using RITEK stencils. If you have some issues, like solder icicles, stripping issues, great height gap in solder ball after high-temperature reflow, RITEK stencils resolve those issues and increase the product yield rate for your customers.

2. IC Package Application

RITEK electroforming stencils with good-shaped openings, smooth side walls, and high-precise alignment make flux smoothly and continuously drop, and balls accurately drop on exact UBM. Moreover, RITEK stencils help you solve missing balls, extra balls, or bridge to boost product yield rate for your customers and reduce total cost afterwards.

II. Etching stencil

RITEK etching stencils are made by two-side etching, which reduces a risk of ball shift or missing ball situations. RITEK etching stencils features great opening uniformity and fabulous flatness. In comparison to electroforming stencil, an etching stencil is cost-competitive and has a short lead time.

Surface-mount Technology

WELLTECH ENERGY (WTE) is a professional LCD SMT (Surface-mount Technology) production solutions provider. Our SMT solutions are diversified used for IT and electronic products. The products provided include control boards for TFT-LCD Panels (TV/desk Top/ note books), other electronic products and light bar, etc.